Orco Repel™ FF – Fluorocarbon and PFAS Free Water & Aqueous Stain Repellent

Fluorocarbon containing water and oil repellent chemicals have been a vital part of the Textile and Coating industry for many years. The ability easily repel water, oil, soil and stains allowed for an entirely new markets for textiles and textile related coatings for outerwear, activity wear, barrier fabrics, sportswear, home furnishing, carpets – the list goes on and on.

Fluorocarbon containing water and oil repellent chemicals have been a vital part of the Textile and Coating industry for many years. The ability easily repel water, oil, soil and stains allowed for an entirely new markets for textiles and textile related coatings for outerwear, activity wear, barrier fabrics, sportswear, home furnishing, carpets – the list goes on and on.

Over the last few years, investigations by the Environmental Protection Agency and related International Environment Monitoring Agencies have determined that the high toxicity of C8 and C6 containing fluorocarbons remain in the environment – forever – and can find their way into drinking water, and are very harmful to the environment.

Welcome to the world of “buzzwords” such as Forever Chemicals, PFAS, PFOS, and many other terms you are hearing in the news, nightly.

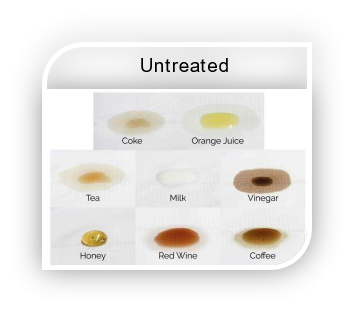

Unfortunately, due to the chemistry and excellent performance of these existing Fluorocarbon based water and oil repellents, there has been no way to “just switch to something less harmful” and still maintain the high level of performance, ease of use and application flexibility that Fluorocarbons provide. To date, there has been no chemical or product developed that matches ALL of the performance and application features of Fluorocarbon Based Water and Oil Repellents.

Unfortunately, due to the chemistry and excellent performance of these existing Fluorocarbon based water and oil repellents, there has been no way to “just switch to something less harmful” and still maintain the high level of performance, ease of use and application flexibility that Fluorocarbons provide. To date, there has been no chemical or product developed that matches ALL of the performance and application features of Fluorocarbon Based Water and Oil Repellents.

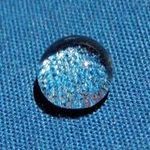

The Organic Dyes and Pigments Technical Team have been monitoring the PFAS situation, industry developments and legislative movements as we worked towards finding replacement(s) for Fluorocarbon Based Water and Oil Repellents. We are proud to announce the development of ORCO REPEL™ FF, a PFAS & Fluorine-Free Water and Aqueous Stain Repellent for use in the Textile and Coating Industries. ORCO REPEL™ FF is a high performance water repellent textile finishing agent made from PFAS Free, non-fluorinated and renewable materials. ORCO REPEL™ FF is suitable for all types of fibers and protects finished textile goods from challenging rain conditions, mechanical stress and various aqueous household stains.

Performance

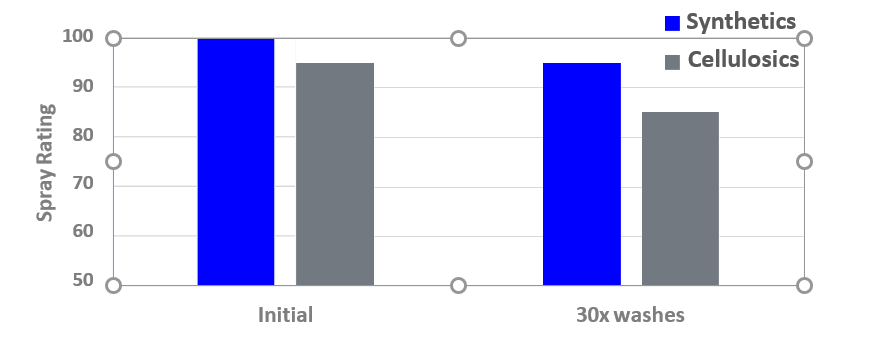

- Superior water repellency on natural fibers, synthetics and blends providing long-lasting protection from rain and aqueous stains

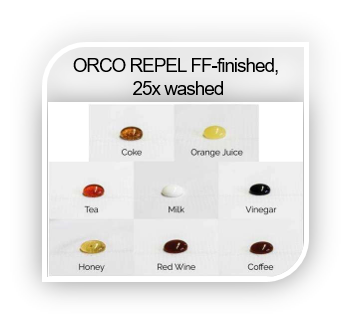

- Excellent durability to home laundering allowing 25x washes and more

- Breathability of fabrics is retained thus providing comfortable wear of finished articles

- Engineered to enhance the useful life of the fabric while providing a soft hand, increased comfort and reduced mark-off.

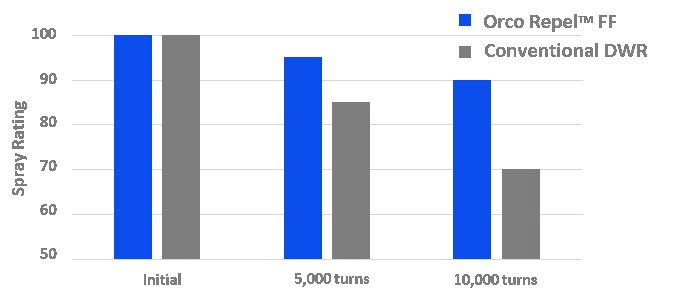

- Outstanding abrasion resistance making the water repellent finish suitable for most challenging technical applications

- High stability and process ability of finished goods including excellent lamination properties for post-processing of finished fabrics

- Compatible with commonly used wetting agents, fillers and crosslinking agents

- Free of halogenated compounds and alkyl phenol ethoxylates (APEO)

Testing: Stain Repellent Properties on Woven PES

Testing: Spray Rating & Resistance to Home Laundering

Water Spray Repellency (AATCC 22) after Home Laundering (ISO 6330, 40°C)

Water Spray Repellency (AATCC 22) After Martindale Abrasion (ISO 12947)

Application

ORCO REPEL™ FF is used to impart water repellency to textile substrate of all fiber types. For good durability, use of a ORCO CROSSLINKER™ NIR is required. The pH of the application liquor should be adjusted with acetic acid (pH 4-5) before adding ORCO REPEL™ FF through a finely meshed sieve or filter.

ORCO REPEL™ FF can be easily dispersed in water by stirring. The use of high speed impellers or stirrers should not be used as the emulsion can be damaged irreversibly due to high shear.

The goods must be thoroughly pre-treated and should be free from surfactants, fiber finish oils, dyeing assists, lubricants, residual alkali or multivalent salts, as small quantities may cause deterioration of the water repellency effect.

| Polyester and Polyamide | Cotton and Polyester/Cotton | |

| ORCO REPELTM FF

Wet pickup Drying Curing |

50 – 125 g/L

10 – 20 g/L

30-60% 320oF for 1 min 340oF for 30 sec |

70 – 125 g/L

20 – 25 g/L

60-80% 320oF for 1 min 340oF for 30 sec |

For heavy or poorly drying substrates, the dwell time must be extended. Lower curing temperatures with increased dwell time (280oF for 5 min) can be used depending upon the desired water repellency effect along with a suitable cross linker, preliminary trials should always be conducted.

To restore the full effect of the finish after each wash, a heat treatment (tumble drying or ironing) is necessary.

Storage

The product is sensitive to frost and heat and must not be stored at temperatures below 40oF or above 100°F. Irreparable damage is possible. In the case of suspected frost or heat damage, the usability of the product has to be checked before processing.

We are continuing to evaluate the properties and testing performance of the ORCO REPEL™ FF in our labs and in production settings. Please check back here often or check with your ORCO Representative as we will be updating our current information and presenting additional performance results for the ORCO REPEL™ in this BLOG.